our solutions.

For you, we combine precision, performance, flexibility and cost-effectiveness in holistic automation and robot technology. Intelligent special machines ensure stable production, standardized components ensure high cost efficiency. If desired, we can also provide your production with drive and control technologies, intelligently designed manual workstations and production management systems (MES) for planning. Last, but not least, we also provide you with the right software to network your machines and systems!

All advantages

at a glance.

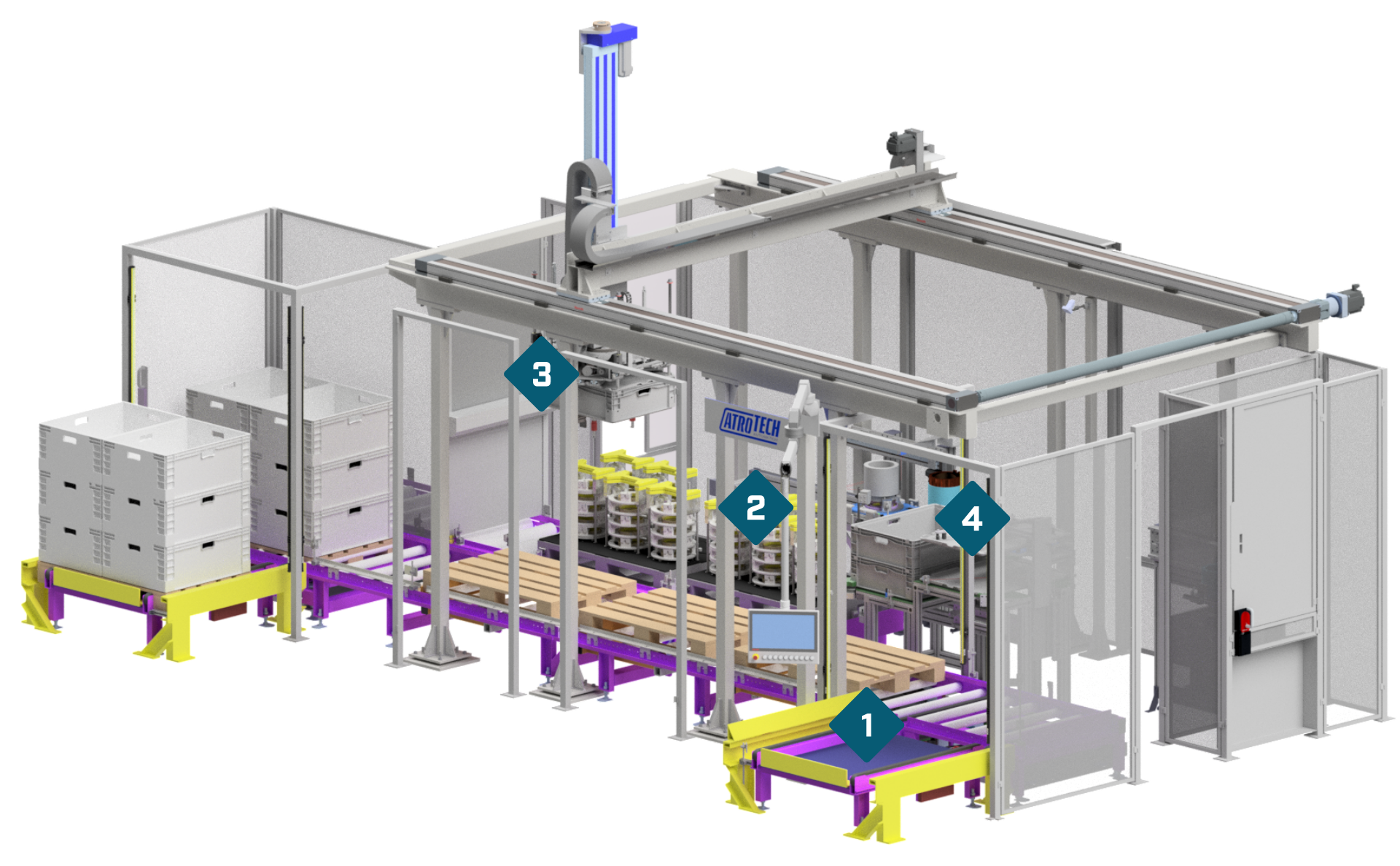

Handling of

Stators and Rotors

E-Mobility Powertrain

Interface to automatic loading system

High variety of parts thanks to fully automatic set-up in cycles

All in one gripper system for box and component handling

Reach into the box using the camera system and place it in the correct position on a WT system

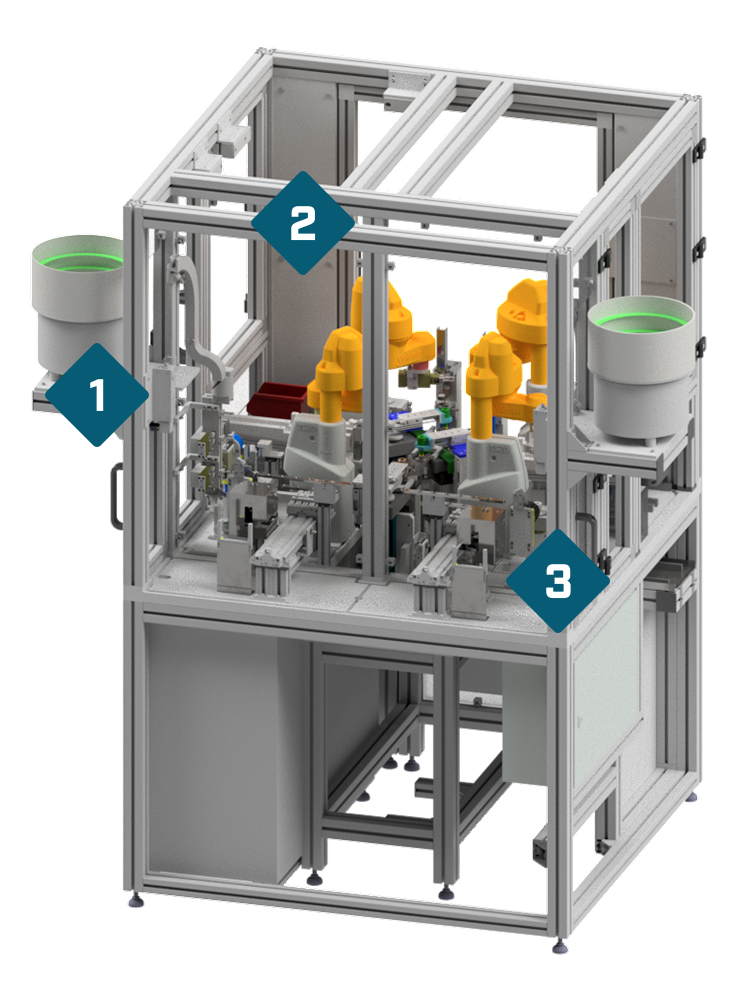

Test automation

Checking parts can be so easy!

Here we show you how easy:

Simultaneous feeding and removal of components to a grinding machine

Fully automatic measurement with dynamic control loop adjustment for downstream grinding systems

Fully automatic stabilization and calibration processes

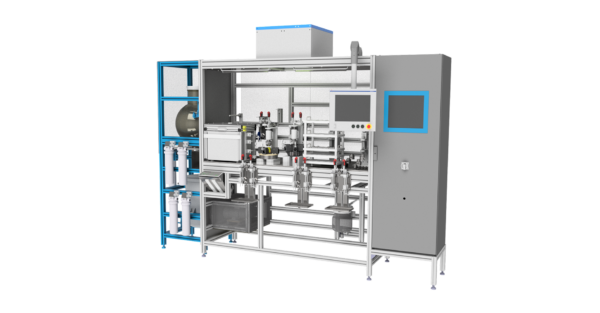

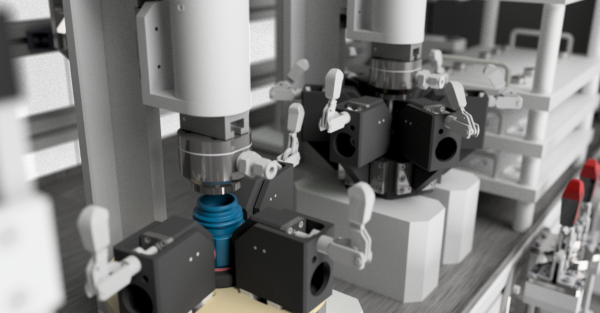

Cleanliness and tightness

Test benches according to VDA19

Particle cleanliness is one of the most important quality factors in the automotive industry and in numerous other sectors. However, checking and documenting so-called technical cleanliness represents a challenge for OEMs and suppliers. The particles specified as critical are often located on internal surfaces of a component, for example in the oil channel of a crankcase, meaning that testing using direct measuring methods is not possible. With our systems, residual dirt analyzes can be carried out in accordance with VDA 19 or ISO 16232. There, the particles are first extracted from the components in a cleaning step with liquid, collected on a filter and then analyzed according to customer specifications.

Process automation

You want to get your processes in shape,

automate them partially or even completely?

Then you have found the right partner in us.

Interest

aroused?

Martin

Wünsche

personnel manager

+49 951 / 40760-0

info@atrotech.de